Produits phares

Analysis of Dust Generation and Removal Methods in Jaw

2022-3-22 The dust collecting measure of jaw crusher in the early stage mainly includes two types--spray and dust collecting, and the relevant dust-proof devices are mainly set at the inlet and outlet of crusher. However, the actual dust-proof effect of these methods in the production site is terrible, and the main reasons are: When the crusher works, it

Contact

How to solve the dust problem of jaw crusher

2020-11-25 Jiaozuo Zhongxin will talk about the solution to the dust problem of the jaw crusher. 1. Set up a sealing cover at the source of dust, and configure water spray and dust suction devices at the same time. (1) Two water spray nozzles are installed at the inlet and outlet respectively, and the direction of the water nozzle must be reasonable

Contact

Jaw Crusher an overview ScienceDirect Topics

For a jaw crusher the thickness of the largest particle should not normally exceed 80–85% of the gape. Assuming in this case the largest particle to be crushed is 85% of the gape, then the gape of the crusher should be = 45.7/0.85 = 53.6 cm and for a shape factor of 1.7, the width should be = 45.7 × 1.7 = 78 cm.

Contact

Analysis of the cause of dust in jaw crusher

2020-5-20 Analysis of the dust production point of the jaw crusher. The dust production source of the jaw crusher mainly comes from the inlet, outlet and conveying system. The materials to be processed are crushed and crushed by the crusher, and then sent to the next process through the conveyor. In this process, a large amount of dust will be generated, and the concentration is

Contact

How to solve the dust problem of jaw crusher

2020-3-23 Jaw crusher is commonly known as jaw crusher. The jaw crusher produced by our company mainly includes steel plate casting and other types. The crushing cavity is composed of two jaw plates, the moving jaw and the static jaw. and water spray and dust suction devices are also provided. (1) Set two water nozzles at the inlet and outlet. The

Contact

Method to reduce dust pollution of jaw crusher

2021-11-15 A vacuum cleaner can be installed at the discharge port and the inspection port behind the movable jaw of the crushing chamber. The vacuum cleaner of the discharge port vacuum cleaner is about 1000mm away from the discharge port, and the plane of the suction hood is perpendicular to the direction of dust flow; after moving the jaw The connecting duct

Contact

Reduce dust pollution of jaw crusher-Jiaozuo zhongxin

2020-10-28 (1) Two water spray nozzles can be set at each of the three main parts of the inlet, the outlet and the movable jaw crushing cavity. The two nozzles at the manhole point to the inlet; the two nozzles at the outlet are opposite A certain angle is formed to make the sprayed mist form a cross state to achieve a good spray effect; the nozzle at the crushing cavity is set behind the

Contact

How to effectively reduce the Dust Pollution of Jaw Crusher?

2021-8-20 The nozzle at the crushing chamber is located behind the moving jaw at a horizontal angle. 2. Dust collector. Dust collectors are installed separately at the access port at the back of the moving jaw and the discharging opening to control the diffusion of dust by means of dust collector. The collector cover is about 1 meter away from the outlet.

Contact

Jaw Plate Failure and Life Crushing, Screening

2022-6-6 Without this the crusher has to rely on energy and friction to crush the rock. Compaction will also impose increased loads to the crusher as much as five times the normal crushing force. To the opposite,feed material that is too large also affects wear life. A jaw crusher in most applications is a 6 to 1 ratio of feed reduction.

Contact

How to Control Dust in Crushing Plant

2020-11-8 Secondary Crushing Plant. As shown in the flowsheet, there are four exhaust systems in operation in the secondary crushing plant, with additions planned for the system exhausting the underground ore-receiving bins. When the system is completed, a volume of 99,300 cfm will be exhausted from the crushing and screening operations in the secondary

Contact

Analysis of the cause of dust in jaw crusher

2020-5-20 Analysis of the dust production point of the jaw crusher. The dust production source of the jaw crusher mainly comes from the inlet, outlet and conveying system. The materials to be processed are crushed and crushed by the crusher, and then sent to the next process through the conveyor. In this process, a large amount of dust will be generated, and the concentration is

Contact

How to solve the dust problem of jaw crusher

2020-11-25 Jiaozuo Zhongxin will talk about the solution to the dust problem of the jaw crusher. 1. Set up a sealing cover at the source of dust, and configure water spray and dust suction devices at the same time. (1) Two water spray nozzles are installed at the inlet and outlet respectively, and the direction of the water nozzle must be reasonable

Contact

Jaw crusher Lococrush JC Locoproject

The Lococrush jaw crusher is a compact mobile crusher with a unique price-quality / performance ratio. Its high crushing performance and at the same time simple operation and maintenance is ideal for use in the recycling or mining industry. As an option, it is possible to order a number of options diesel pump, water spray against dust

Contact

Jaw Crusher Agri World Mechanical

Jaw Crusher. Jaw crushers are used for crushing rocks and debris from quarries, demolitions and excavations but, compared with hammer crushers, they offer a great advantage over crushing material with high wear factors (granite, river

Contact

® C Series™ jaw crushers Proven reliability and

2021-7-16 ® C Series™ jaw crushers have proven to be reliable and productive in thousands of mining, quarrying, recycling and industrial applications with up to 11,000 jaw crusher installations since 1975. Developed to crush the hardest ores and rocks, jaw crushers also perform outstandingly with less demanding materials.

Contact

Jaw Plates: How to Choose the Right One for

2021-9-2 Different jaw plates have different scopes of application, which also determines the working efficiency of the jaw crusher. Only by choosing the correct jaw plate can the service life of the crusher be guaranteed. Fote machinery

Contact

SPECIFICATION SHEET roco9

2021-9-29 • Dust suppression system (Installed as Standard) with filtration for dust control (Water Jets) ready for hooking up to your water main on site. Spray bars + jets installed to Crusher Feed, Under Crusher Boxon End of Main Discharge Conveyor. • Compact machine yet all panels for maintenance open fully and floor on catwalk lift up for any

Contact

SANDVIK UJ640E MOBILE JAW CRUSHER

2021-9-9 Crusher level sensor . Radio remote control with umbilical cord as back-up. Frequency inverter for the crusher Automatic lubrication for the jaw Dust suppression spray system on crusher and discharge conveyor Electrical power outlet 125A Natural fines conveyor with support Maintenance platforms for service and maintenance

Contact

SPECIFICATION SHEET roco9

2021-9-29 ROCO R9R Jaw Crusher • ROCO R9R Jaw Crusher is suitable for use in all quarry, mining, demolitionrecycling industries. • Dust suppression system (Optional Extra) with filtration for dust control (Water Jets) ready for hooking up to your water main on site. Spray bars + jets installed to Crusher Feed, Under Crusher Boxon End of

Contact

How to configure sand and gravel aggregate production

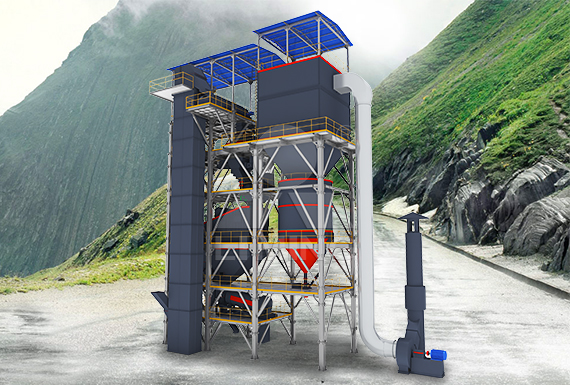

2021-8-25 In addition to the advantages and disadvantages of the jaw crusher + cone crusher system, this system also has some characteristics: it can meet the requirements of large output capacity; but the process is complex and the project investment is high. The dust removal system consists of two parts: water spray dust removal and bag dust

Contact

How to solve the dust problem of jaw crusher

2020-11-25 Jiaozuo Zhongxin will talk about the solution to the dust problem of the jaw crusher. 1. Set up a sealing cover at the source of dust, and configure water spray and dust suction devices at the same time. (1) Two water spray nozzles are installed at the inlet and outlet respectively, and the direction of the water nozzle must be reasonable

Contact

How to solve the dust problem of jaw crusher Shanghai

Shanghai banghuai will talk about the solution to the dust problem of the jaw crusher. 1. Set up a sealing cover at the source of dust, and configure water spray and dust suction devices at the same time. (1) Two water spray nozzles are installed at the inlet and outlet respectively, and the direction of the water nozzle must be reasonable

Contact

Jaw crusher Lococrush JC Locoproject

The Lococrush jaw crusher is a compact mobile crusher with a unique price-quality / performance ratio. Its high crushing performance and at the same time simple operation and maintenance is ideal for use in the recycling or mining industry. As an option, it is possible to order a number of options diesel pump, water spray against dust

Contact

Portable Jaw Crushers MEKA Concrete Plants

Just call +90-312-397-91-33 and we will help you in any way we can. You can also send an e-mail to sales@mekaglobal, or fill in the inquiry form if you would like to pass us a detailed inquiry or project information. Use the Call Back option if you

Contact

® C Series™ jaw crushers Proven reliability and

2021-7-16 ® C Series™ jaw crushers have proven to be reliable and productive in thousands of mining, quarrying, recycling and industrial applications with up to 11,000 jaw crusher installations since 1975. Developed to crush the hardest ores and rocks, jaw crushers also perform outstandingly with less demanding materials.

Contact

How to pick the best product for jaw crusher plates?

2021-3-15 The jaw plate is a most crucial element in the jaw crusher device as well as its life of solution is straight affecting the complete jaw crusher machine. Hence, you must take into . The Fote machinery additionally recommends you to use the affordable spray dust suppression; since it can contest the water to grime as well as hence, reach out

Contact

SPECIFICATION SHEET roco9

2021-9-29 ROCO R9R Jaw Crusher • ROCO R9R Jaw Crusher is suitable for use in all quarry, mining, demolitionrecycling industries. • Dust suppression system (Optional Extra) with filtration for dust control (Water Jets) ready for hooking up to your water main on site. Spray bars + jets installed to Crusher Feed, Under Crusher Boxon End of

Contact

How to Control Dust in Crushing Plant

2020-11-8 Secondary Crushing Plant. As shown in the flowsheet, there are four exhaust systems in operation in the secondary crushing plant, with additions planned for the system exhausting the underground ore-receiving bins. When

Contact

SANDVIK QJ341 Porter Group

2021-10-13 MOBILE JAW CRUSHER TECHNICAL SPECIFICATION The QJ341 is the largest in the Q-Range of tracked jaw crushers and the flagship of the range. Utilizing Sandvik’s unrivalled design and manufacturing expertise, it is one of the best-selling track mounted mobile jaw crushers in the world today. Designed for quick set-up and ease of operation.

Contact

The BIG News In CrushingScreening Is Compact!

2022-2-8 The Model 20SJ is a 10”x20” stationary jaw crusher. Utilizing the same crusher as our Model 20TJ, this machine also has instant hydraulic adjustable jaws that allow output product sizes ranging from ¾” up to 3”. Likewise, dust suppression is also standard on this machine. These crushers are also popular with landscapers, small builders/

Contact