Produits phares

Beneficiation of Barite Dumps by Flotation Column; Lab

2015-12-10 Barite deposit at Mangampet is one of the world’s largest deposits containing around 61 million tonnes of recoverable barite. Beneficiation of low grade barite dumps interlocked with schist and slate gangue was studied using amine as collector (reverse flotation) to avoid the collector coating on barite. Instead of conventional flotation cells, flotation column was opted

Contact

Beneficiation of Barite Dumps by Flotation Column; Lab

After fluorite-barite mixed flotation, fluorite-barite separation flotation, and anti- flotation of lead and zinc minerals, the fluorite concentrate with 97.35% CaF2 and barite concentrate with 95

Contact

Barite Beneficiation Process and Plant Flowsheet

2016-4-9 The Barite Beneficiation Process is one of flotation, it is used as an ingredient in “heavy mud” for oil-well drilling, for which purpose specifications

Contact

(PDF) OPTIMISATION OF BARITE FLOTATION

2022-2-8 2.4.4 Barite-fluorite flotation in cell In the first step (roughing flotation ), the consumptions are 100g/t and 500g/t, respectively for the collector and

Contact

Barite Processing Methods and Machines,Barite flotation

2022-5-27 1. Barite hand selection method. After the raw ore is mined, simple manual selection is a common beneficiation method for many small mines. Due to the high geological grade and stable quality of some mines, qualified barite products can be selected according to the difference in color and density between barite and associated minerals.

Contact

Barite Beneficiation Process Fodamon Machinery

Combined process flow Barite associated with sulphide ore is usually processed by gravity separation flotation combined process. Taking the barite quartz calcite type ore separation as an example, in the flotation gravity separation combined process, by adding sodium silicate and collector to the flotation cell to remove quartz impurities, the barite and calcite mixed ore is

Contact

Flotation studies of fluorite and barite with sodium

2019-1-1 Obviously, barite showed higher recovery than fluorite in a strong acidic environment (pH 2). The maximum recoveries of fluorite and barite were 81.89% and 83.24% reached at pH 11, respectively. As observed, fluorite showed a quite similar flotation response to barite in the pH range 3–11. Download : Download high-res image (137KB)

Contact

Method of processing bariteBeneficiation process

2022-5-22 A combination of classification (initially screens to remove the coarser 'impurities', then hydrocyclones to remove the finer 'impurities' with some barite loss), gravity (calcite/fluorspar/silica from barite and sulphides from barite) and flotation (oleic acid/alkyl sulphonates/sulphates with sodium silicate as the dispersant and neutral to alkaline pH barite

Contact

Bacillus licheniformis a potential bio-collector for Barite

2022-1-1 Barite was recovered up to 87% (at pH = 3) in sole-mineral flotation experiments, and flotation of the mixed sample, also, proved a successful selective separation of barite (76% recovery) from quartz at the bio-collector dosage of 6.55 × 10 3 cells/ml. Adsorption kinetics study showed that the pseudo second-order model could represent cell

Contact

barite beneficiation Xinhai

2022-1-17 01 Physical Impurity Removal in Barite Beneficiation Gravity Separation. Gravity separation is based on the density difference between barite and associated minerals. The raw ore is crushed and ground to a certain size and enters the gravity separation equipment to remove gangue.. When the particle size of barite grained is larger than 2mm, it is usually separated by

Contact

Barite Beneficiation Process Fodamon Machinery

Combined process flow Barite associated with sulphide ore is usually processed by gravity separation flotation combined process. Taking the barite quartz calcite type ore separation as an example, in the flotation gravity separation combined process, by adding sodium silicate and collector to the flotation cell to remove quartz impurities, the barite and calcite mixed ore is

Contact

Flotation studies of fluorite and barite with sodium

2019-1-1 Obviously, barite showed higher recovery than fluorite in a strong acidic environment (pH 2). The maximum recoveries of fluorite and barite were 81.89% and 83.24% reached at pH 11, respectively. As observed, fluorite showed a quite similar flotation response to barite in the pH range 3–11. Download : Download high-res image (137KB)

Contact

4 Common Barite Beneficiation Methods Mining-pedia

2020-4-24 3. Barite Flotation Process. Barite flotation process is mainly based on the difference of physical and chemical properties of barite and associated minerals. It is commonly used in eluvial barite ore and hydrothermal barite ore associated with sulfide ore and fluorite. For the separation of fine-grained ores and gravity separation tailings

Contact

flotation cell for mineral ore beneficiation

flotation cell for mineral ore beneficiation  Flotation Cell, Minerals Beneficiation, Ores Beneficiation Capacity: Volume of the cell can be from 1 cubic feet t to 40 cubic feet and hp could be from 1 to 7.5 hp. Applications: Superfine dry powder of none-metal ores such as calcite, marble, limestone, coarse whiting, talc, barite

Flotation Cell, Minerals Beneficiation, Ores Beneficiation Capacity: Volume of the cell can be from 1 cubic feet t to 40 cubic feet and hp could be from 1 to 7.5 hp. Applications: Superfine dry powder of none-metal ores such as calcite, marble, limestone, coarse whiting, talc, barite

Exceptional Barite Processing Methods and Machines

2022-4-15 The flotation machine is widely used for barite flotation. Here is a case of barite flotation beneficiation. Barite Ore Magnetic Separation Barite ores often associate with siderite, pyrite and other magnetic iron oxide minerals. Magnetic separation is applied to remove impurities such as magnetic iron-containing minerals in barite ore.

Contact

(PDF) Beneficiation of Azara Barite ore using a

PDF On Nov 15, 2018, H.E. Mgbemere and others published Beneficiation of Azara Barite ore using a combination of jigging, froth flotation and leaching Find, read and cite all the research you

Contact

Lauryl Phosphate Flotation Chemistry in Barite Flotation

Barite has numerous applications including barium mud for oil well drilling, manufacture of elemental barium, filler for stone and rubber industries, and contrast material for X-ray radiology for the digestive system. Currently, froth flotation is the main method for the beneficiation of barite using fatty acid as a typical collector. In this research, it was found that lauryl phosphate is

Contact

Bacillus licheniformis a potential bio-collector for Barite

2021-11-9 The maximum adsorption density of 1.33 × 10 10 cells/g was achieved at pH = 3 for barite, six times higher than quartz. Flotation experiments revealed that cell-assisted separation was more effective than metabolite-facilitated flotation, either for single mineral or the mixed sample (barite mixed with quartz).

Contact

Beneficiation of fluorspar by column flotation SpringerLink

The amenability of column flotation for the beneficiation of fluorspar was investigated, and the overall performance of the column flotation was compared to the performance of the existing conventional flotation cells at the plant. It was established that improved grades and recoveries could be obtained by adopting column technology. Acidspar concentrates assaying 97%

Contact

BENEFICIATION OF AZARA BARITE ORE USING A

Using froth flotation, barite samples with concentration of over 95% BaSO 4 have been obtained from different sources: tailings [4], from complex iron ore in Bulgaria [5] 96.32% and 91.26% respectively, from low grade barite ore from Myanmar [6] up to 88 % BaSO 4 from low grade barite in India [7]. Flotation of barite using

Contact

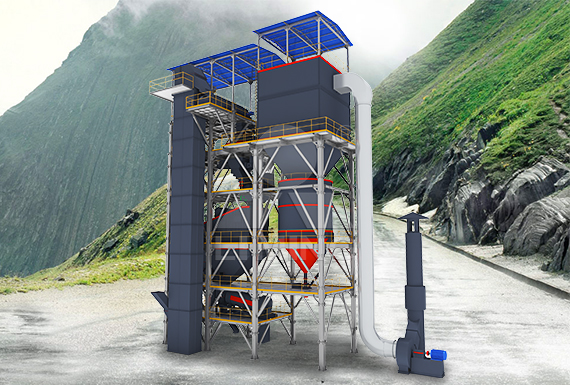

Barite Beneficiation Plant McNally Sayaji

Barite Beneficiation Plant. MSEL Bangalore has installed two barite beneficiation plants near Kadapa, Andhra Pradesh. Mechanical Flotation Cell; Column Flotation Cell; High Rate Thickeners; Press Filters; Registered Office Ecospace Business Park, Campus-2B, 11F/12, Rajarhat,New Town, Kolkata 700 160, West Bengal, India

Contact

flotation cell for mineral ore beneficiation

flotation cell for mineral ore beneficiation  Flotation Cell, Minerals Beneficiation, Ores Beneficiation Capacity: Volume of the cell can be from 1 cubic feet t to 40 cubic feet and hp could be from 1 to 7.5 hp. Applications: Superfine dry powder of none-metal ores such as calcite, marble, limestone, coarse whiting, talc, barite

Flotation Cell, Minerals Beneficiation, Ores Beneficiation Capacity: Volume of the cell can be from 1 cubic feet t to 40 cubic feet and hp could be from 1 to 7.5 hp. Applications: Superfine dry powder of none-metal ores such as calcite, marble, limestone, coarse whiting, talc, barite

Barite Beneficiation Process ballmillgrinder Manufacturer

A barite ore, the raw ore contains about 12% BaS04, and the embedded particle size is fine. The barite concentrate with grade BaS04 > 95%, specific gravity 4.35% and recovery 84.12% was obtained by magnetic separation impurity removal flotation process, and good technical and economic indexes were obtained.

Contact

Exceptional Barite Processing Methods and Machines

2022-4-15 The flotation machine is widely used for barite flotation. Here is a case of barite flotation beneficiation. Barite Ore Magnetic Separation Barite ores often associate with siderite, pyrite and other magnetic iron oxide minerals. Magnetic separation is applied to remove impurities such as magnetic iron-containing minerals in barite ore.

Contact

[PDF] Beneficiation of Azara Barite ore using a

In this research, Jigging, Froth Flotation and leaching have been used to beneficiate barite ore from Azara, Nasarawa State Nigeria. Chemical analysis on the ore indicates that it contains 53.09% of Ba and 11.52% S with a specific gravity value of 3.207±0.03. After the jigging operation, the specific gravity values of the underflow and overflow are 3.77±0.029 and

Contact

Lauryl Phosphate Flotation Chemistry in Barite Flotation

Barite has numerous applications including barium mud for oil well drilling, manufacture of elemental barium, filler for stone and rubber industries, and contrast material for X-ray radiology for the digestive system. Currently, froth flotation is the main method for the beneficiation of barite using fatty acid as a typical collector. In this research, it was found that lauryl phosphate is

Contact

Bacillus licheniformis a potential bio-collector for Barite

2021-11-9 The maximum adsorption density of 1.33 × 10 10 cells/g was achieved at pH = 3 for barite, six times higher than quartz. Flotation experiments revealed that cell-assisted separation was more effective than metabolite-facilitated flotation, either for single mineral or the mixed sample (barite mixed with quartz).

Contact

RECENT DEVELOPMENTS IN FLOTATION FOR THE

2011-9-25 flotation, are discussed earlier (1-2). Various techniques like carrier flotation, oil flotation. agglomerate flotation/shear flocculation (3), electroflotation (4-5), vacuum floatation, column flotation, Jameson flotation cell have been developed to separate valuable particles from gangue. Though the techniques were proved to be effective

Contact

Barite Flotation In Greece Philippe Lange

Barite Flotation In Greece. FOB Reference Price: Get Latest Price Barite mining processes generally contain three processes and steps, crushing, grinding and beneficiation.Crushing of barite mining processes and steps.Crushing process is the first step in all barite mining processes and steps.Jaw crusher is often used in primary crushing process.Big barite stones are

Contact

flotation cells for ore beneficiation muzycznepszczolki.pl

It consists of a square base cells fitted with a receding type impellerflotation cell for barite beneficiation mining. May 09, 2013 Copper ore beneficiation and concentration . The froth flotation cells recover the copper from sulfide ores by chemically attaching the copper to gypsum, lead, magnesite, manganese, tungsten,flotation

Contact